All Cutterheads Are Not Created Equal.

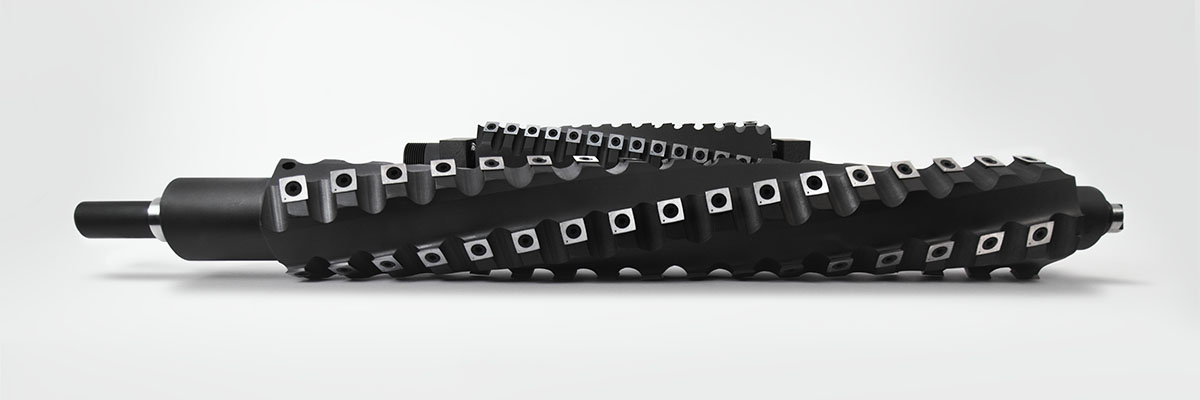

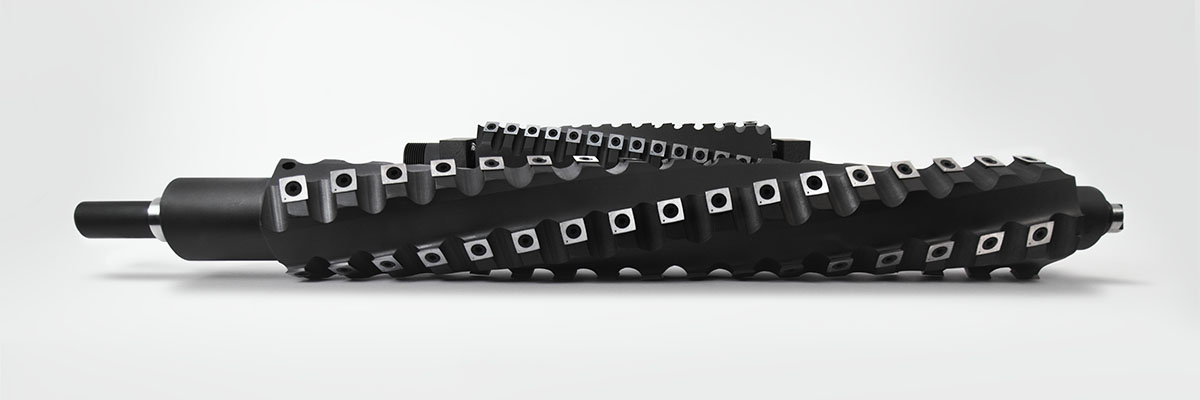

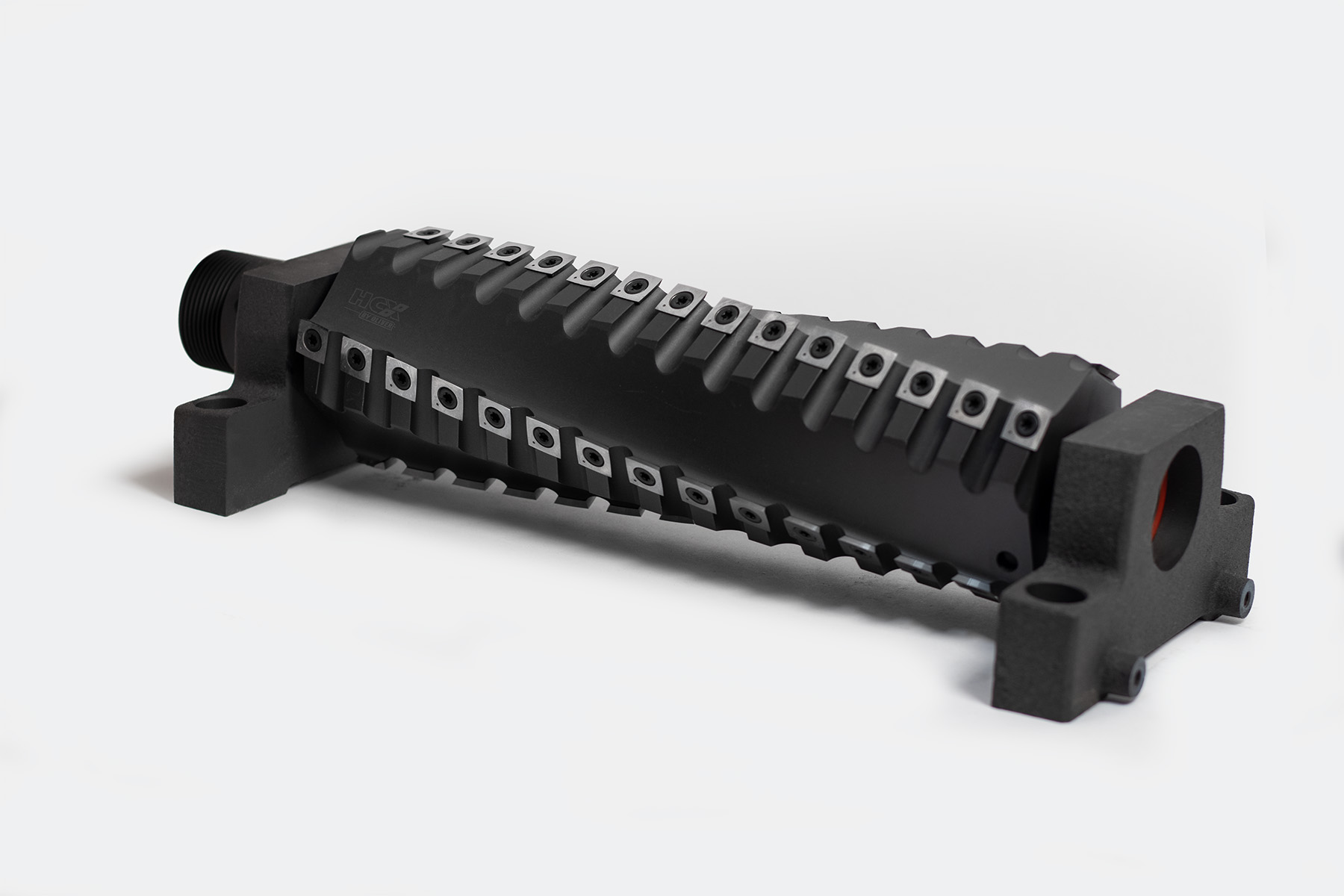

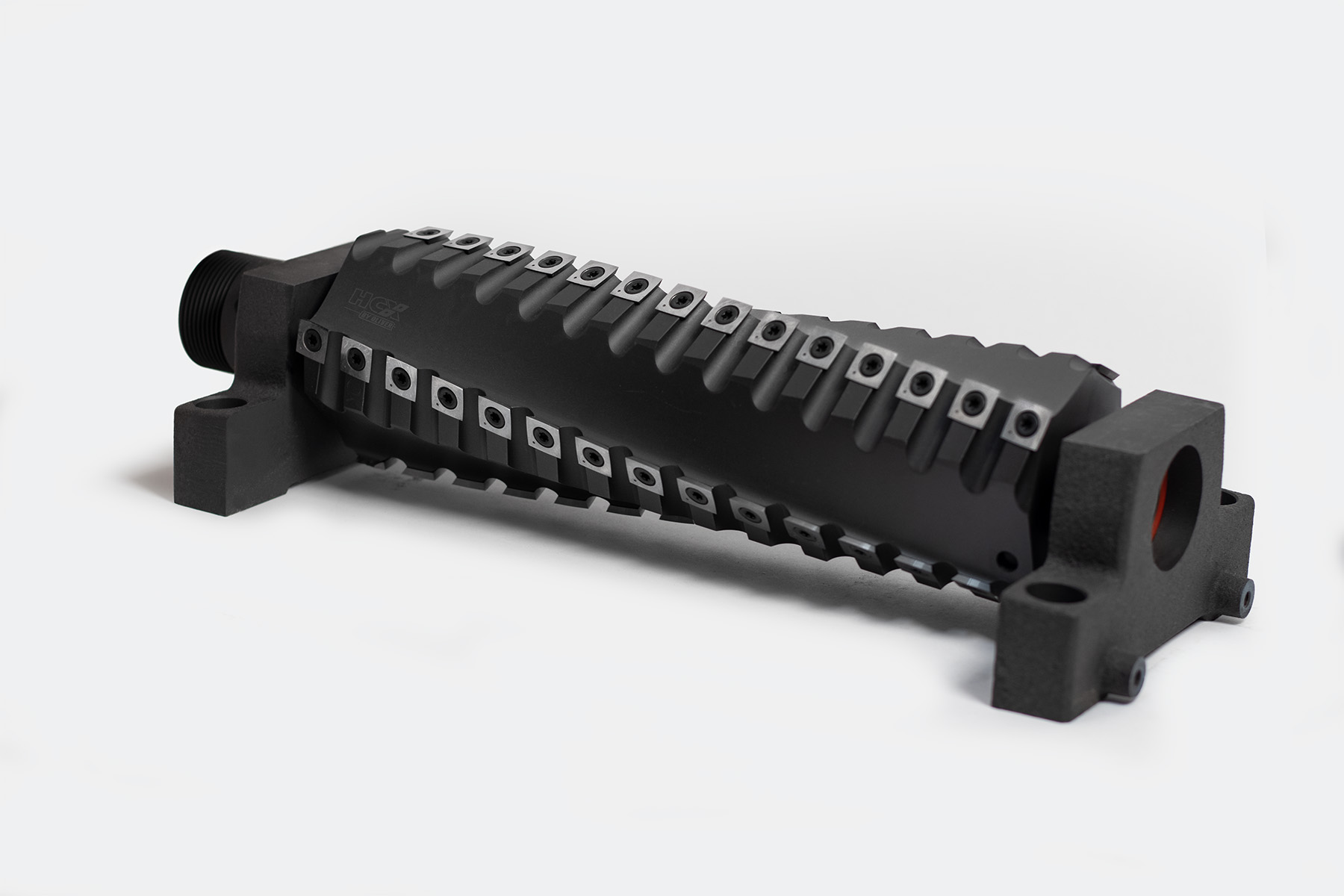

Oliver has been manufacturing industry leading planers and jointers for over a century. We have also been outfitting our machines with our own brand of high quality helical cutterheads and inserts for over 20 years. Our manufacturing experience and knowledge of cutterhead technology is used in our HCX cutterheads for our entire product line of planer and jointer machinery.

What is a helical cutterhead and why does it matter to your wood shop? Helical means it has teeth arranged in a spiral pattern around the cutterhead, similar to a spiral staircase. This design helps make smoother cuts, reduces noise and clears material more efficiently.

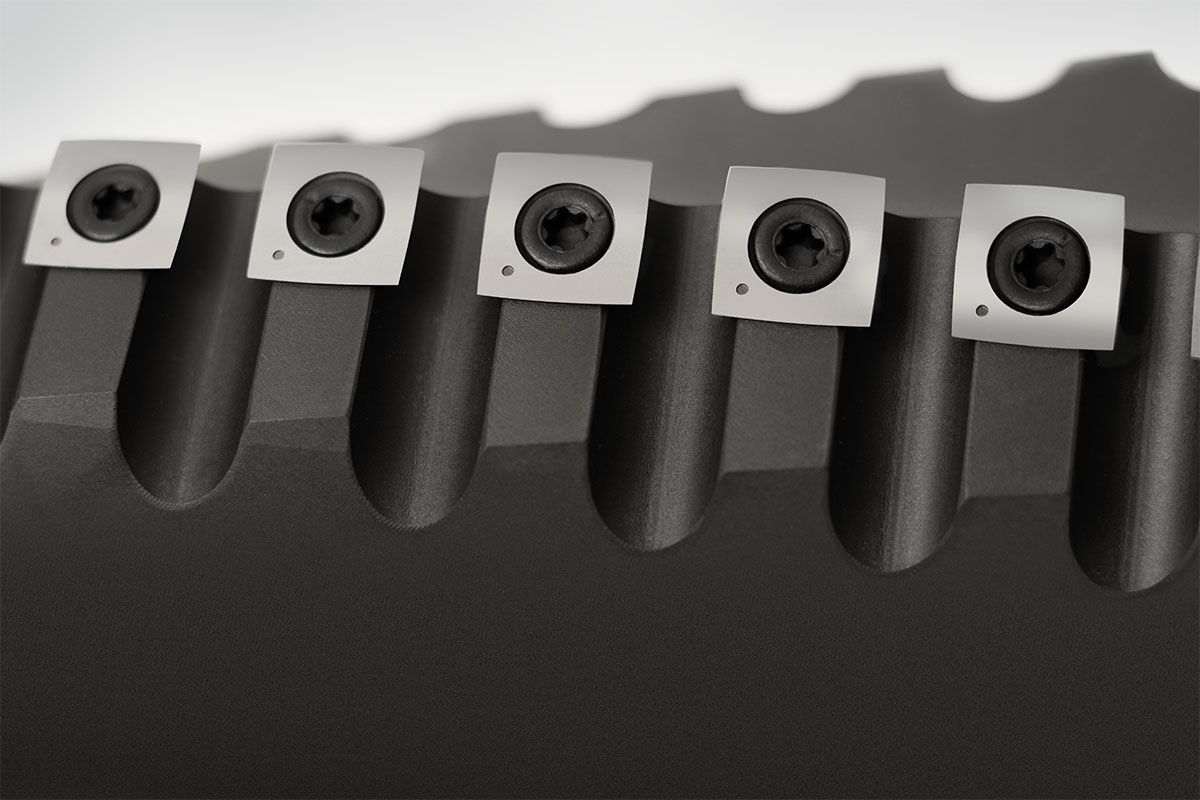

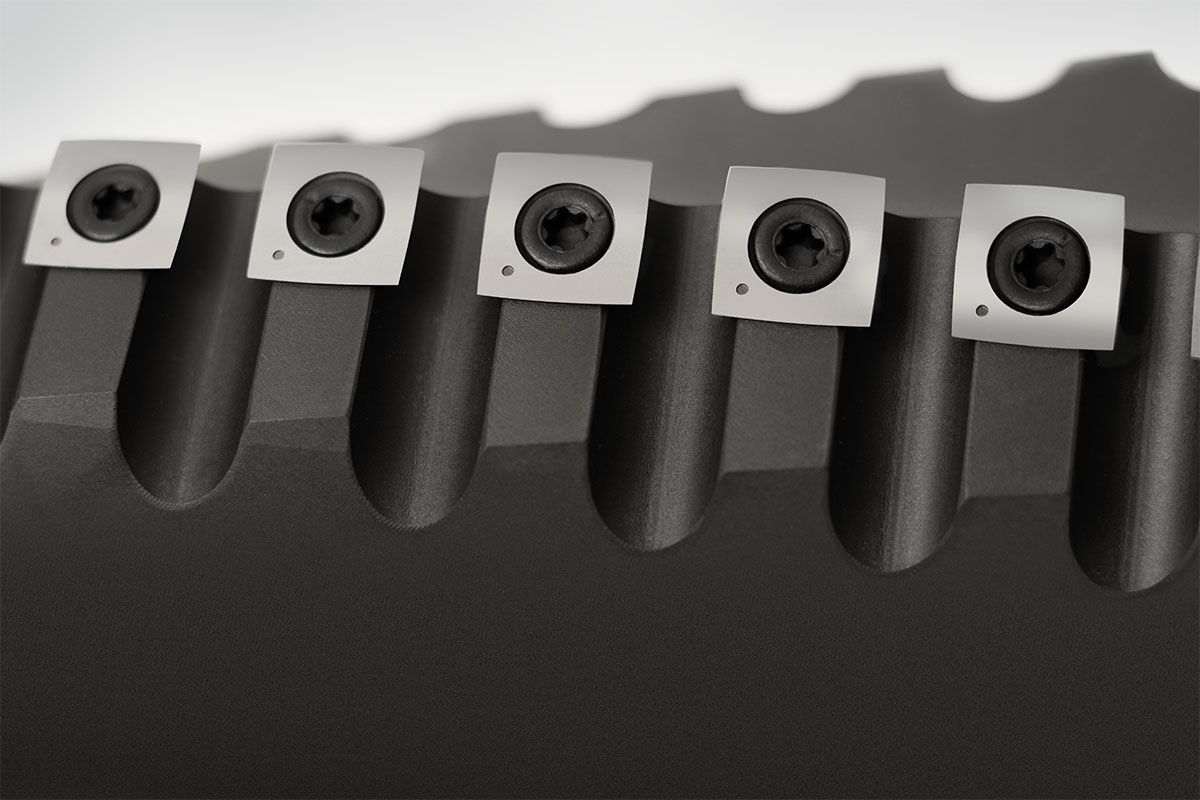

Helical cutterheads also provide a shearing action which allows the teeth (four-sided inserts) to slice through the wood fibers like scissors cutting paper at slight angles, rather than just smashing through them at a right angle.

This combination of helical and shearing action results in cleaner, more precise cuts with less tear-out, less wear and a better overall finish needing less sanding. The added benefit is the inserts themselves are four-sided, letting you easily rotate them individually as they wear or get damaged.

Our four-sided carbide inserts provide quality cuts and a long service life, reducing the frequency of blade changes. The Oliver HCX Helical cutterheads and inserts are engineered to give the smoothest finish and longest life in our machines working with the toughest hardwoods, providing consistent and superior results with each pass.

- Helical and Shearing Design: Purposely placed four-sided carbide inserts along helical axis ensure smoother and quieter performance, minimum tear out and provide a superior finish requiring less sanding.

- Optimized for each Oliver machine for performance, finish, chip evacuation and longevity.

- Cost Effective Quality: Our HCX Cutterheads are developed alongside each of our line of machines to provide consistent, professional results along with a long, cost-effective service life.

- Precision Craftsmanship: Enjoy precise and reliable results across various wood types, including the most challenging hardwoods.

-

Decades of industry leading helical cutterhead engineering and development.

-

Designed specifically for our complete product line of planer and jointer machinery for optimal performance.

-

Superior materials and craftsmanship, fine-tuned by our factory engineers.

Straight Knife – Straight knife cutterheads have been around since the turn of the last century. Three or more straight blades cover the length of the cutterhead and interact with the wood surface on a perpendicular (90 degree) plane. This results in very loud operation plus added stress and wear on all moving parts. These still get the job done, but new technology always wins and has many cost and performance benefits over the life of your machine.

Segmented – Segmented cutterheads use smaller sections of straight knives arranged around the circumference of the cutterhead. Like straight knives these still interact with the wood surface on a perpendicular (90 degree) plane resulting in very loud operation and wear. These provide better performance than regular straight knives, and easier/less expensive replacement but have the same drawbacks as straight knives that newer helical technology solves.

Spiral – Spiral cutterheads consist of multiple two or four sided knife inserts (typically 15mm square), arranged parallel around a helical axis on the cutterhead. Like segmented and straight knives these interact with the wood surface on a perpendicular (90 degree) plane resulting in loud operation and wear to the cutting surfaces.

Helical and Shearing – All of Olivers HCX cutterheads use a helical and shearing design with 4-sided carbide insets. Shearing smaller pieces of material at slight angles to the wood piece being fed. This process produces cleaner results, substantially lowers the operational sound volume, provides a long service life and makes it easier for your dust collection system to collect wood chips.